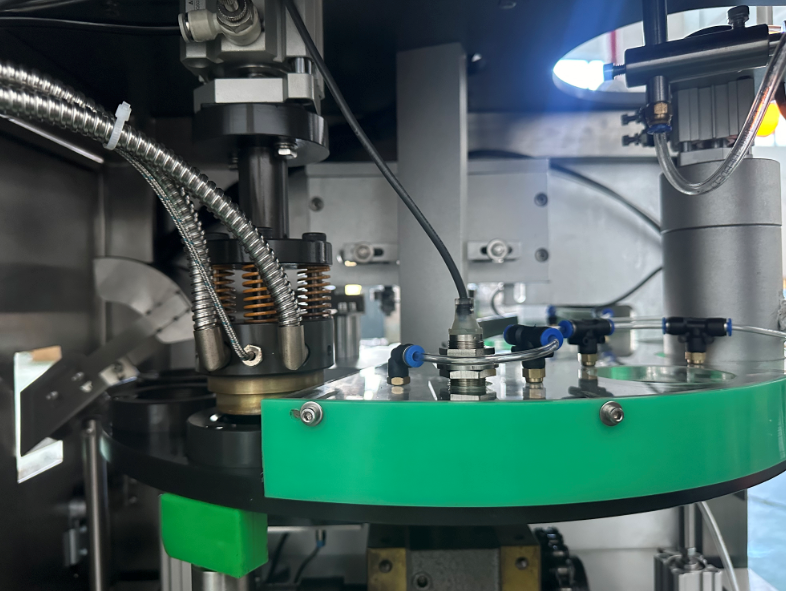

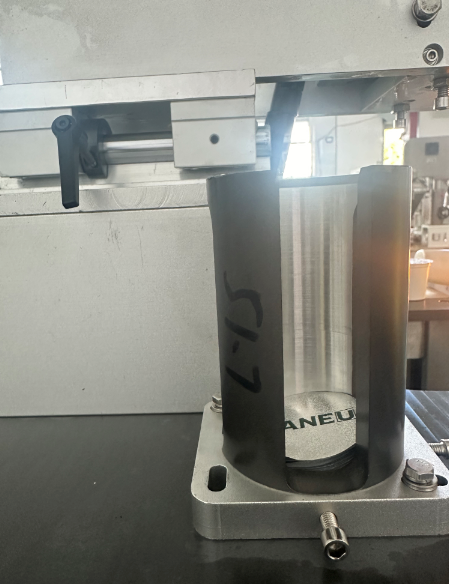

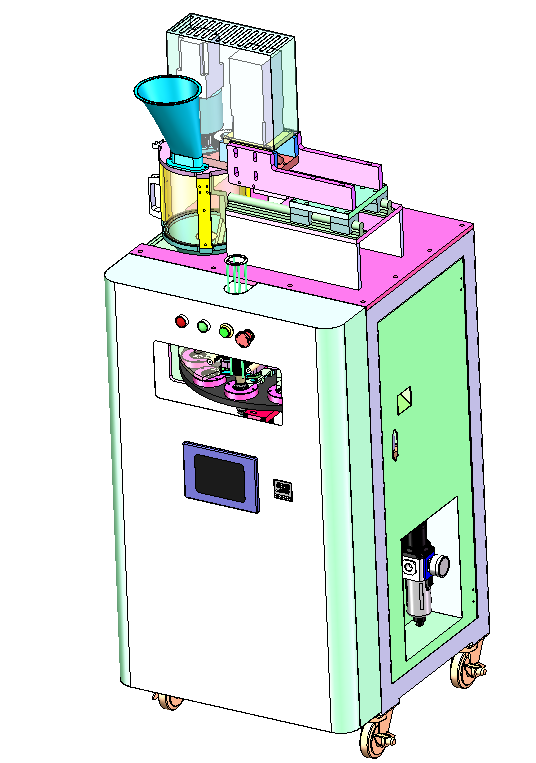

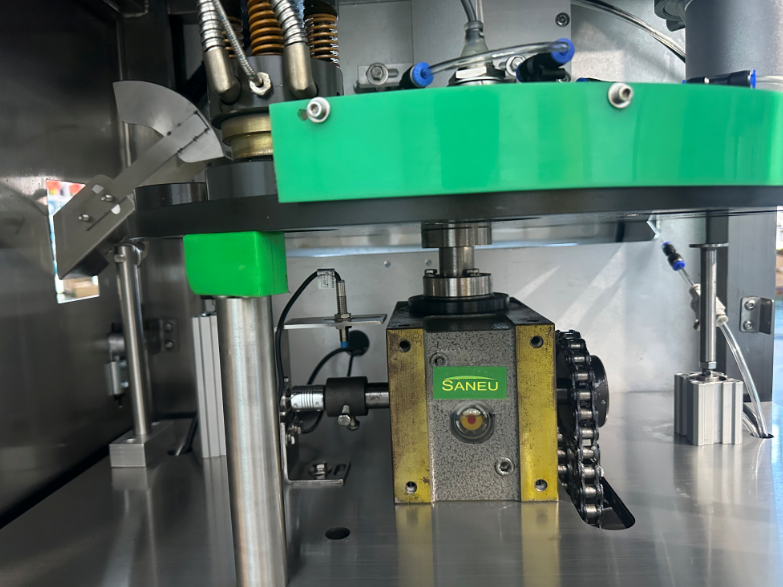

The aluminum cup or plastic cup to be produced is placed neatly on the tube bucket, and automatically inserted into the cup holder (positioning die) through the cup dropping device. The cup holder is driven by the turntable and stays at different stations respectively. The powder that needs to be filled is put into a sealable conical barrel, and the plastic cup that stays intermittently on the filling station is accurately and automatically injected through a screw type quantitative filling valve directly connected with the barrel. The chain plate continues to rotate, and the plastic cup that has been filled with powder is quickly taken to different stations. The filling head of each station can feed the plastic cup. Different filling capacity can be obtained by adjusting the number of servo turns on the touch screen, and the sealing work of different cup sizes such as aluminum cups and plastic cups can be completed by replacing different copper heads

-----------------------

|

filling accuracy |

≤±2% |

|

hopper volume |

15L |

|

productivity |

2100pills/hour |

|

suitable cups |

single cup, nespresso, lavazza |

|

filling range |

5--15g |

|

Power supply |

Single phase 220V, 2KW |

|

Main motor power |

0.2KW |

|

heating range |

160--300 C |

|

air pressure |

0.6-0.8MPA |

|

Air consumption |

0.4(m3/h) |

|

Noise |

<70db |

|

Dimension (LXWXH) |

650X650X1800mm |

|

Machine weight |

300kg |

|

Nitrogen flushing |

available |