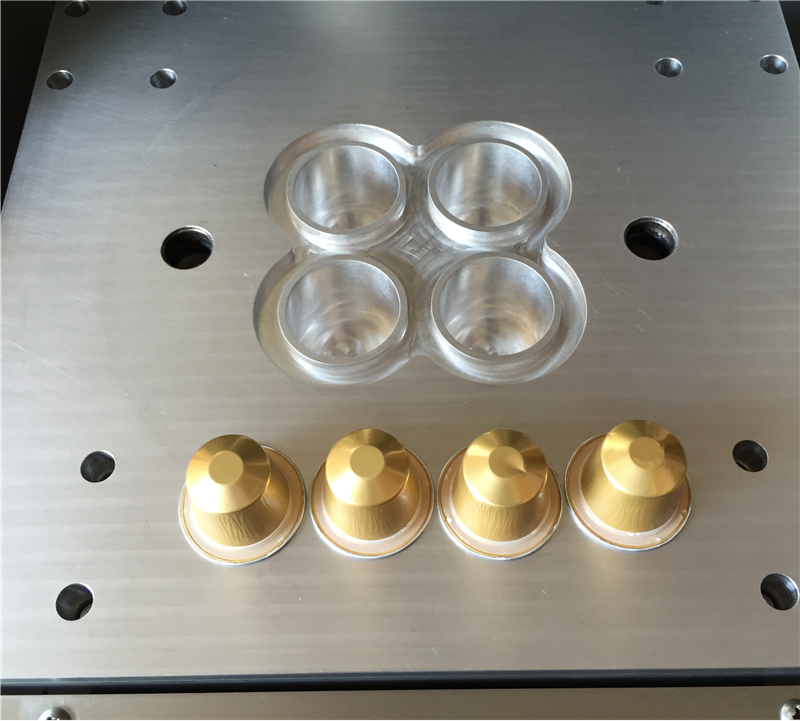

Automatic Nespresso capsule sealing machine with Nitrogen

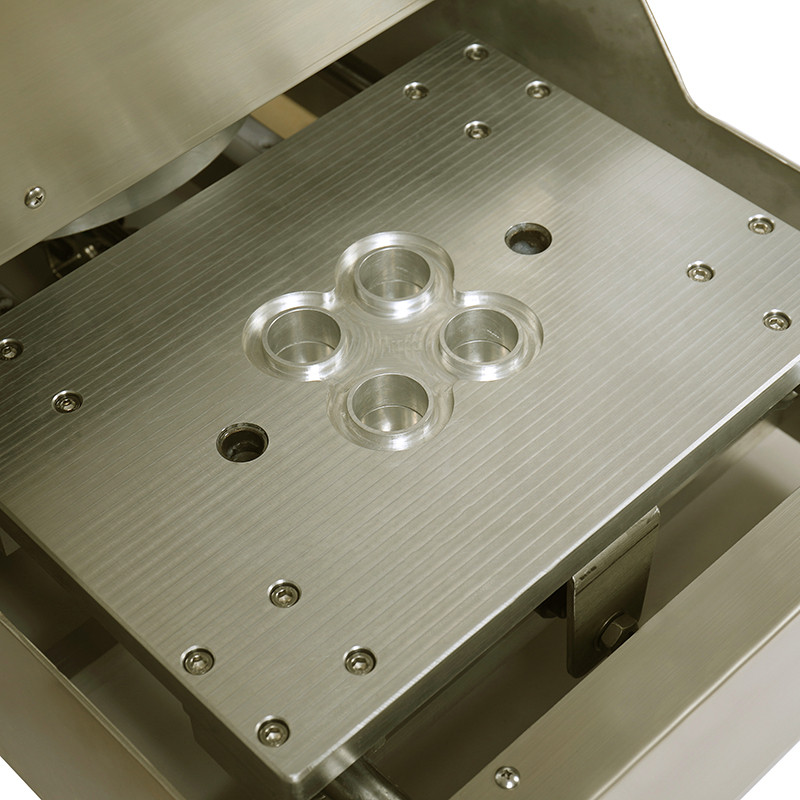

SANEU focus on coffee capsule packaging, Nit SX-4 Nitrogen System Sealer adopts auto intelligent heat sealing system, Sealing Temperature 190--300 °C, power supply 220V,50Hz,720W. Compact and unique structure. Stainless steel frame and well-known electrical elements. manual polishing on machine frame.

Nitrogen flushing process: 1. Nitrogen chamber close. 2. Pump out air in Chamber. 3. fill nitrogen into chamber. 4. Capsules sealing. 5. sealing heads go up. 6. Chamber go up

Specifications

| Aluminum Cup Diameter | 37mm |

| Foil Lid Diameter | 34.5 mm |

| Cavities Number | 4 |

| Heating Head | 4 single heads |

| Sealing Way | Auto intelligent heat sealing |

| Capacity | 300--500 pcs/h |

| Sealing Time | 2 S |

| Sealing Temperature | 190--300 ℃ |

| Driven Type | Electrical+ Pneumatic drive |

| Power Supply | 220V,50Hz, 720W |

| Air Source Demand | 500 ml/min |

| Overall Dimension | 920*530*980mm |

| Gross Weight | 150KG |

| Packing Way | Wooden Case |

|

Kindly Note: Machine can be designed for not only alu Nespresso capsule, but also K cup, Lavazza and others on your request. |

|

Electrical elements equipped with machine

|

Touch screen |

Weinview(Colorful) |

|

PLC |

Japan Mitsubishi |

|

Cylinder |

China brand |

|

Heating tube |

Taiwan brand |

|

Temperature control system |

China brand |

|

Stainless steel thickness |

3 mm, manual polishing |

machine working Video

Nitrogen flushing process:

1. Nitrogen chamber close. 2.air extraction in Chamber. 3. fill nitrogen into chamber.

4. Capsules sealing. 5. sealing heads go up. 6. Chamber go up

About Saneu

Saneu focus on coffee capsule packaging (K cup, Nespresso, Lavazza etc.) and concentrate every corner of machines. We are professional coffee capsule packaging equipment manufacturer.

- Our business covers 30 countries and regions

- 60% business from customers' recommendation

- Our distributors located around the world can provide local service quickly

- Provide private solutions for different customers needs